Have no hesitation in

choosing a valve

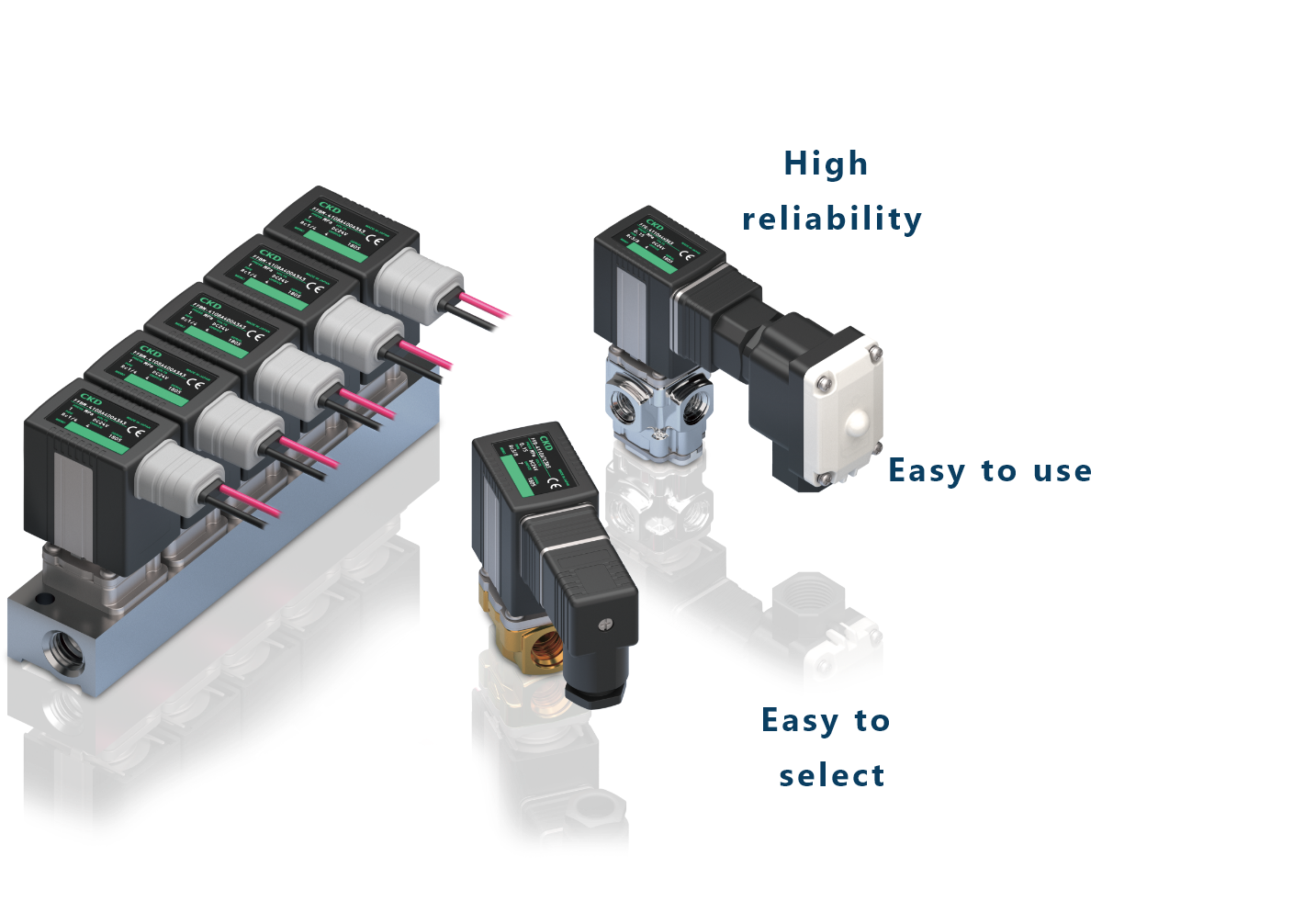

MULTI-FIT®

for a Wide Variety of Fluids

Direct acting 2, 3-port solenoid valve

MULTI-FIT® <FFB/FFG Series>

NEW STANDARD

for Fluid control valves

MULTI-FIT® is a direct acting solenoid valve compatible with various fluids that has been refined for reliability, ease of use, and ease of selection. The “High-function standard equipment” allows you to use it in a variety of situations/applications without worries.

Have you ever felt hard-pressed about these issues with solenoid valves?

- Durability with Dry Air (inert gas)

- Operation noise of solenoid valves

- AC coil whirring sound

- Corrosion and rust of channels (wetted parts)

- Fluid leakage during coil

replacement and maintenance - Compatibility with carbon neutral efforts

Recommended for the following situations

- For use with any fluid

- Supports compressed air, dry air (inert gas), water, oil, and vacuum.

It reduces the burden of stock of replacement parts and maintenance.

- For use in quiet environments

- Quiet design that suppresses the metallic noise characteristic of solenoid valves.

It can be used in quiet environments such as medical institutions and laboratories.

- Requiring a highly corrosion-resistant solenoid valve

- High corrosion resistant material is used for the plunger and flare pipe.

Corrosion resistance is greatly improved and the occurrence of rust at wetted parts is reduced.

- Reduce maintenance complexity

- Pressure resistant vessel structure is adopted to reduce external leakage risk.

There is no fluid leakage during coil replacement, and the coil can be attached/detached with a simple operation.

- ReduceCO2 emissions

- Significantly reduces power consumption and waste through longer service life.

Contributes to factory-wide carbon neutrality compliance.

- Complying with international standards

- Compliant with EU standards and RoHS Directive.

Supports CE Marking on customer machine products.

High reliability High functionality as standard

- High durability of 20 million cycles

-

20 million cycle durability even with dry air

(Under CKD test conditions) - The integrated plunger and wear ring reduce sliding resistance and realize durability equivalent to that of general air components.

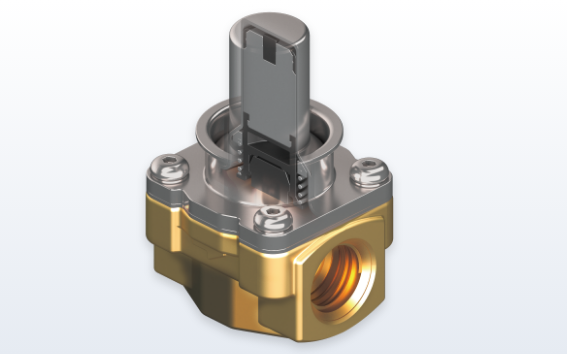

- Uses highly corrosion-resistant materials

- The integrally molded flare pipe is weld free reducing rust on wetted parts

- High corrosion-resistant material is adopted for the plunger and flare pipe to greatly improve corrosion resistance.

Dezincified brass is used for the brass body to reduce the risk of internal leakage.

- Coil with full-wave rectifier provided as standard (AC type)

- Prevents coil burnout and buzzing due to overcurrent

- Prevents buzzing of AC (current) coils generated when foreign matter is lodged.

Realizes significant energy savings of 11 W→4.5W. (60% reduction compared to conventional CKD products, for valve size 3)

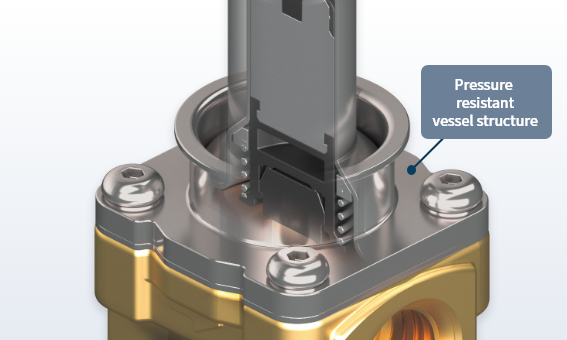

- Pressure resistant vessel structure adopted

- Reduces risk of external leakage

- The flow path is not exposed when the coil is replaced, and there is no risk of fluid leakage.

Easy to use High convenience

- High quietness

- With the adoption of the noise dampening rubber, metallic noise during operation has been reduced. It can be used safely even in quiet environments such as medical institutions and laboratories. (35% quieter compared with conventional models)

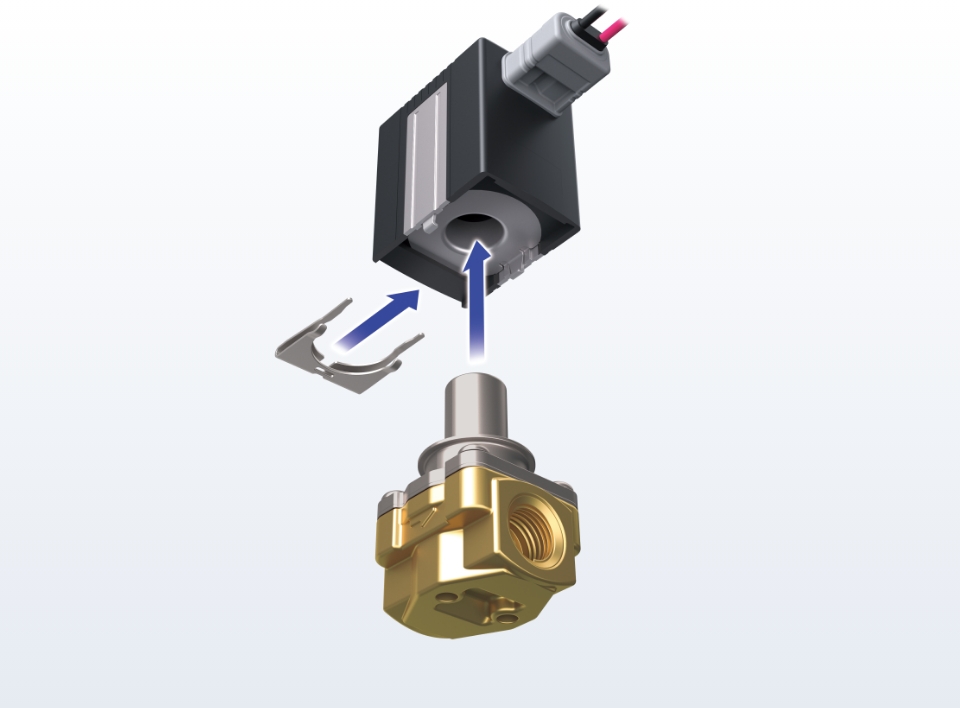

- High maintainability

- The coil can be attached and detached with a push-in clip. The coil can be easily attached/detached without removing the screw or nut.

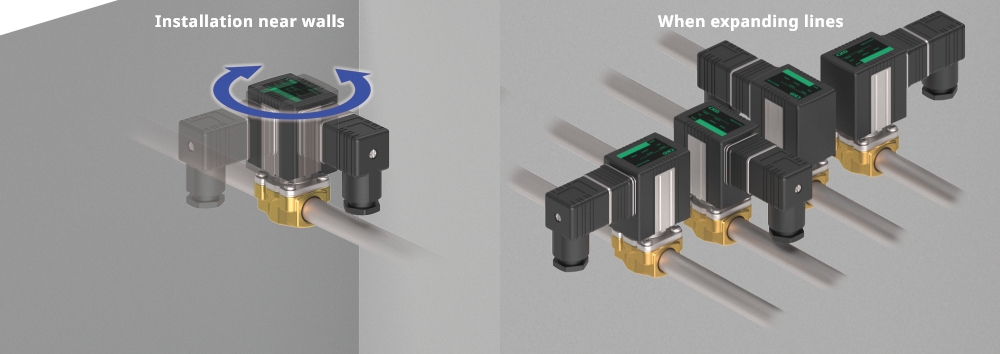

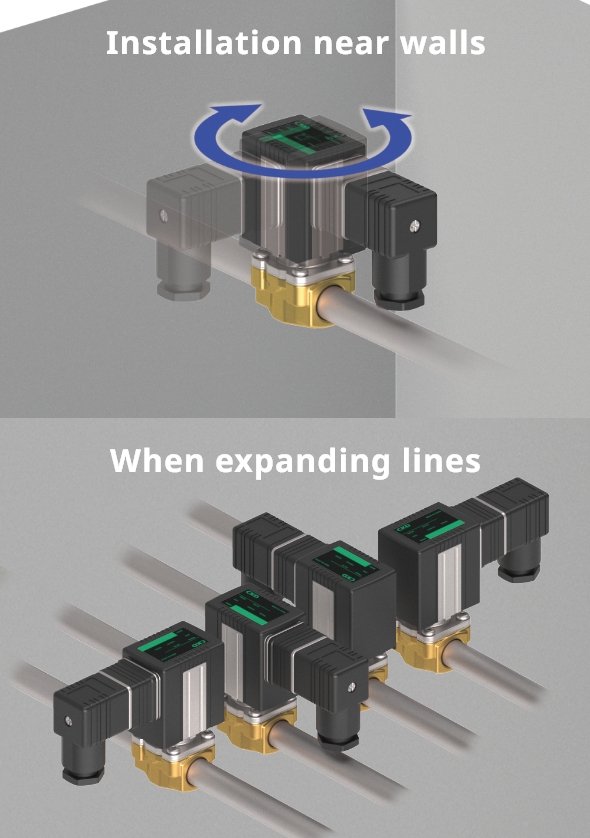

- High installability

- The coil rotates 360° and enables flexible layout. It has a high degree of freedom in installation, and enables effective use of narrow spaces near walls that are difficult to handle. Flexible installation even when expanding lines.

Easy to select Wide variation

A wide range of variations are available to suit various situations.

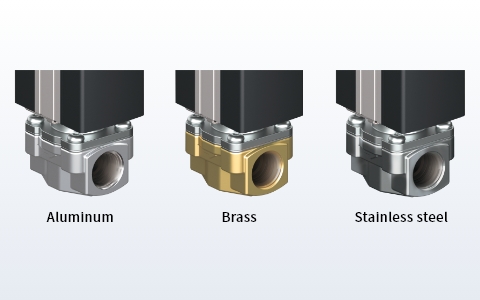

- Material

- Material variations compatible with a wide range of fluids

| Body material |

Aluminum |

|---|---|

| Brass | |

| Stainless steel |

| Sealant material |

NBR(Nitrile rubber) |

|---|---|

| FKM(Fluoro rubber) | |

| EPDM(Ethylene propylene rubber) |

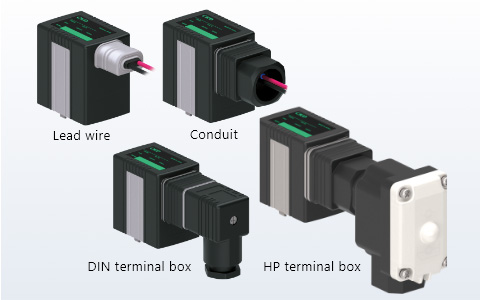

- Piping/wiring

- Piping/wiring variation corresponding to a variety of mounting methods for various equipment and facilities

| Port thread standards |

Rc |

|---|---|

| G | |

| NPT |

| Electrical connections |

Lead wire |

|---|---|

| DIN terminal box | |

| HP terminal box | |

| Conduit |

- Compatible with global standards

- Compliant with EU standards and RoHS

- Supports CE Marking on customer machine products.

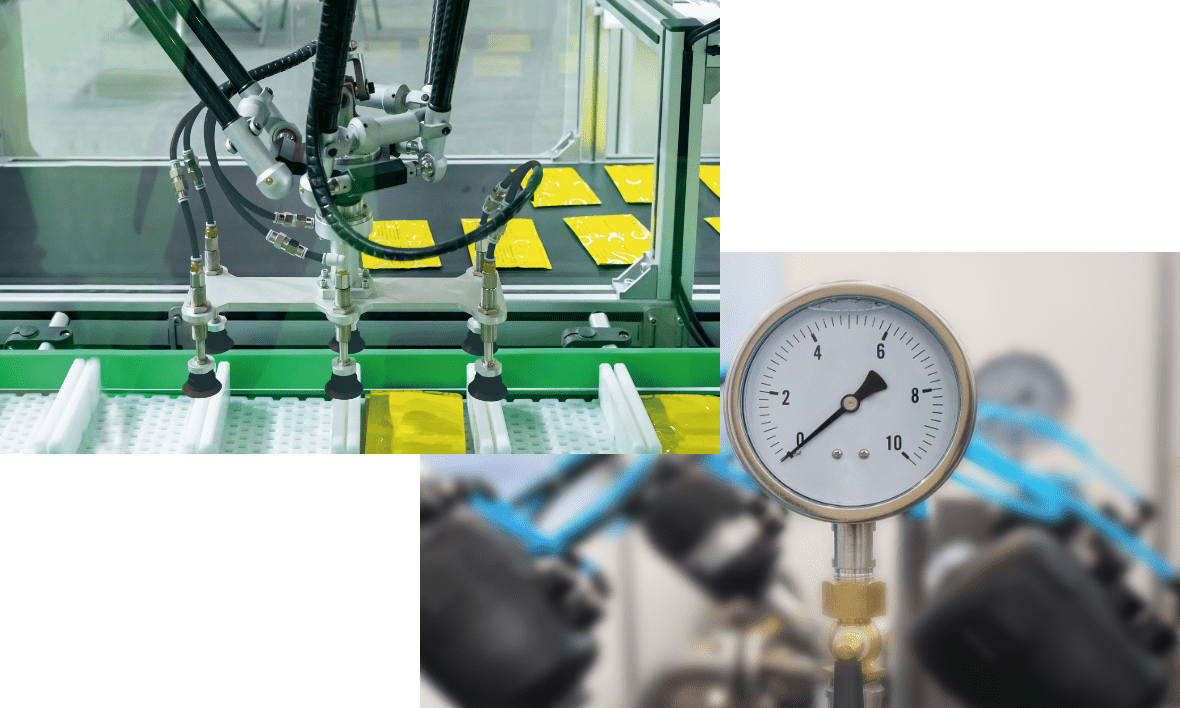

Examples of applications

MULTI-FIT® for various fluids can be used in a variety of applications regardless of the industry.

Examples of Fluid Use

- Compressed air

- Supply of compressed air, control of air blow, etc.

- Dry air(inert gas)

- For supply of dry air in rechargeable battery manufacturing processes, N2 (inert gas) purge, etc.

- Water

- Water supply and drainage control of cleaning solution, temperature control by water cooling, etc.

- Oil

- Control of turbine oil, coolant, etc.

- Vacuum

- Vacuum switching control, suction control, etc.

Compatible with carbon neutral

By reducing waste through reduction of power consumption and longer service life, it is compatible

with carbon neutrality. Contributes to the realization of a sustainable society.

Energy saving

Low wattage specification that significantly reduces power consumption

Reduction of CO2emissions*

Integrated molding without welding reduces CO2 emissions during manufacturing

Long service life*

Reduces maintenance due to breakdowns and waste

* Compared to conventional CKD products

Having problems with the conventional solenoid valves?

Feel free to contact CKD if you are switching from a conventional solenoid valve or considering new ones.

Multi-fluid compatible MULTI-FIT® will meet your needs.